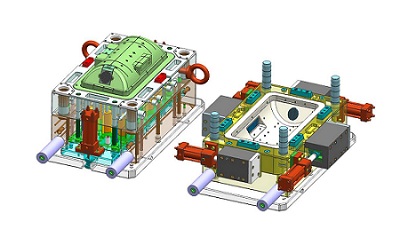

R&D Capacity

Above all, the quality of mould comes from design. Our professional designing team and scientific management process enable the team participation of the whole process, from customer information communicating to solution making, from solution reviewing to data confirmed by customers, and accordingly ensure our final data solutions optimized, accurate, and meeting the standards and requirements of our customers.

Mould CAD

1. Our mould design is subject to U-Trust Mould Design Standard, which, 68 pages, is our long-time accumulation and experience summary of mould technology. Every detail is made as a basis for the designer to rely on.

We trust in personal ability, but we attach more importance to team power, our design group, project group and processing group work together to

2. Design range: 100% mould design

3. Design software: NX8.0 AutoCAD

Mould flow analysis

Mould flow analysis CAE

:

1. The optimal forming scheme is confirmed through analyzing mould flow, which can avoid defects like fusion lines, air entrapment, starved feeding, etc.

2. We provide our customers with product optimization and material selection for reference.

3. Software of finite element analysis is used to help optimize the mechanical performance of products.

Besides mould flow analysis, we also provice other services to assist developping products.

1. Rapid prototyping: machine or 3D-print the shapes of products so as to detect the rationality of product assembly.

2. Simple mould: also known as test mould, with low-cost and fast manufacture, can effectively avoid market risks, and thus provide experimental basis for formal mould.

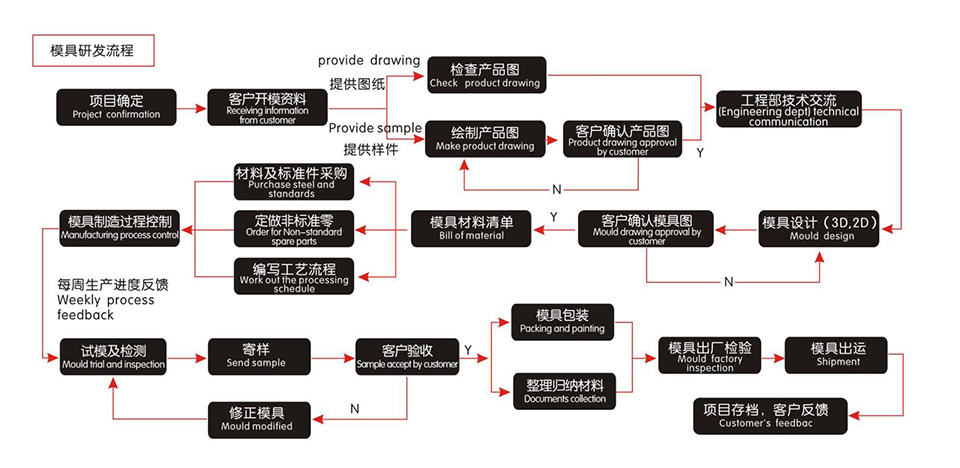

Mould developping process